Understanding the Difference Between Offset Printing and Digital Printing Technology

The advent of digital printing technology has seen the introduction of advance and more exciting printing solutions. Printing isn’t just printing. Whether you are looking for something functional for the office or offering commercial printing services, understanding the different types of printing methods — digital and traditional, can help you choose printing equipment for your next print project.

Offset Printing Technology

Offset printing, also referred to offset lithography is a printing technology that uses plates, which burns the desired print image onto a rubber blanket and is transferred to the printing surface (a sheet of paper perhaps). It a common printing method used in high volume commercial printing, and produce crisp prints that have the professional look.

How does offset printing works? Well, this printing technology is based on the mutual repulsion of oil and water. The print image is burned on print plates, where the printing area gets ink from ink rollers, while the non-printing area gets a film of water, forming a hydrophilic layer that is ink-free.

Benefits of Offset Printing Technology

Lithography printing offers numerous benefits such as

- High image quality, with a greater detail and color reproduction

- Ideal solution a wide range of printing surfaces from paper sheets, wood to leather and metal among others.

- Low printing cost with uncompromising print quality

- Suitable for large printing quantities due to its cost-effectiveness

- The use of computer-to-plate systems (CTP) instead of the conventional computer-to-film system on modern lithography increases quality

- Custom printing ink options are available

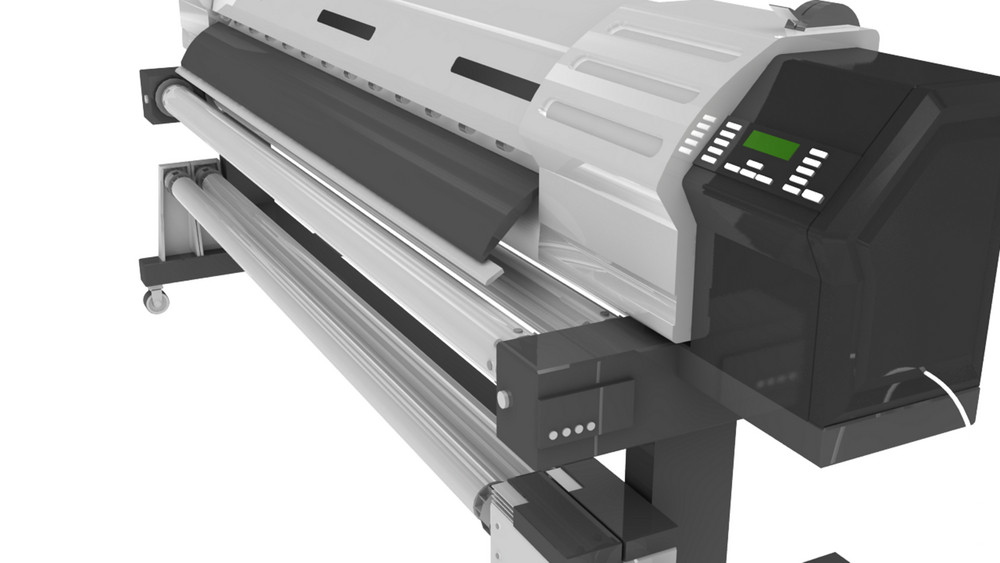

Digital Printing

Digital printing is an advanced printing solution that doesn’t rely on the print plates to transfer an image onto a surface. This method eliminates all mechanical processes associated with conventional printing such as making plates, creating film and color proofs. In place of plates, digital printing uses inkjet type of technology with options such as liquid ink and toner for different types of digital printing equipment.

While offset printing is ideal for high volume commercial printing and produces quality print work, digital printing makes the best choice for low quantity printing for businesses and individuals. Whether it poster printing or business card, digitally produce prints can ensure effective variable data printing. Something that offset printing cannot offer. Let’s look at some of the advantages of digital printing services.

We have seen the advantages of offset versus digital printing, and now you are a step closer to make the right decision. But first, you must understand the features to look for in printing equipment to make the best choice.

Quantity should be the first determiner when choosing a printing machine because it directly impacts the print cost. Offset printing is cost-effective on long runs but costly on short runs. In digital printing, it’s more effective to print low volumes but costly for larger quantities.

Another factor to consider when choosing printing equipment is the printing medium. Offset offers the most flexibility as it can be used in a wide range of printing medium. Digital printing is yet to be used across different printing surfaces that offset effectively prints on.

Also, you need to know the color options available, so if you need monochrome printing, offset printing is the best as it has only two color options, which is more cost-effective. But if you need full-color printing, digital presses feature four-color printing offering benefits in lower up-front costs. Other things to look for include proofing, customization capability, and importantly, the turnaround.

Understanding the different types of printing technology and the features that make them outstanding puts you in a better position to pick equipment that meets your specific printing needs.